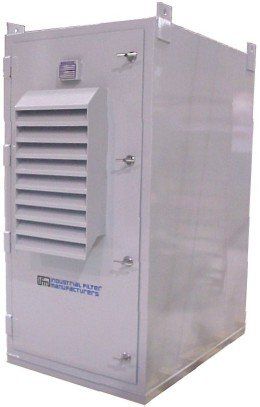

PANEL-STYLE

AIR INTAKE

PANEL-STYLE

AIR INTAKE

The AFP Series panel type housings are designed for removal of airborne particulate for centrifugal compressors, blowers, turbines and other smooth flow machines. These one, two, and three stage filter series incorporate a panel style element with efficiencies up to 99.98% of 0.3 microns. Standard air intake filters have capacities up to 40,000 CFM with outlet sizes up to 42" diameter. Higher capacities and large inlet connections are available. APFC models provide the same protection as standard AFP models with the added benefit of absorbing up to 500 pounds of corrosive, irritating, and odorous gas vapors. All models are furnished with rugged weather hoods. Standard housings are carbon steel and are furnished with rust preventative primer coating beneath all weather paint.

AFP ONE STAGE

AFP Series Panel Style Air Intake Filter/Silencer

Flow Rates To 40,000 SCFM

Efficiencies to 99.98 @ 10 microns

Designed for efficient economical removal of fine airborne particulate and as an inlet filter/silencer. Ideal for protecting engines, and blowers, and reducing inlet noise.

Single stage element no. 12005 is a cleanable element containing 42 square feet of synthetic felt sandwiched between to layers or wire mesh and corrugated to provide high dust holding capacity.

Element frame is rugged galvanized steel with metal grids on the downstream side. A metal strap is provided for ease of removal. Nominal efficiency is 98% @ 10 microns.

AFP TWO STAGE

AFP Series Two Stage Air Intake Filter/Silencer

Flow Rates To 40,000 SCFM

Efficiencies to 99.98 @ 2 microns

Designed for efficient economical removal of ultra-fine airborne particulates and as an inlet filter/silencer. Ideal for protecting centrifugal compressors and turbines, and reducing inlet noise.

PRIMARY STAGE ELEMENT NO. 11293

Primary stage element no. 11293 is a cleanable element containing 29 square feet of synthetic felt sandwiched between two layers of wire mesh and corrugated to provide high dust holding capacity. Element frame is rugged galvanized steel with a metal blowout grid on the downstream side. A metal strap is provided for ease of removal. Nominal efficiency 98% @ 10 microns.

SECOND STAGE ELEMENT NO. 12164

Second stage element no. 12164 is a disposable element containing 135 square feet of waterproof micro-glass media pleated around heavy-duty aluminum spacers. Optimum area provides lowest clean pressure drop. Media is potted to frame to provide additional strength as well as positive sealing. Neoprene sponge gasket is provided on both up and downstream face.

AFPA TWO STAGE

AFPA Series Two Stage Air Intake Filter/Silencer

Flow Rates To 40,000 SCFM

Efficiencies to 99.98 @ 0.3 microns

The APFA series reduces maintenance time and costly equipment by efficiency removing damaging sub-micronic airborne particulates. Ideal for protecting centrifugal compressors and turbines in harsh, corrosive atmospheres, while reducing inlet noise.

PRIMARY STAGE ELEMENT NO. 12099

Primary stage element no. 12099 is a cleanable element containing 39 square feet of synthetic felt sandwiched between two layers of wire mesh and corrugated to provide high dust holding capacity. Element frame is a rugged galvanized steel with metal grids on the up and downstream sides. A metal strap is provided for ease of removal. Nominal efficiency is 98% @ 4 microns.

SECOND STAGE ELEMENT NO. 12166

Second stage element no. 12166 is a disposable element containing 230 square feet of waterproof micro-glass media pleated around heavy-duty aluminum spacers. Optimum area provides lowest clean pressure drop. Media is potted to frame to provide additional strength as well as positive sealing. Neoprene sponge gasket is provided on both up and downstream face.

AFPA THREE STAGE

AFPA Series Three Stage Air Intake Filter/Silencer

Flow Rates To 40,000 SCFM

Efficiencies to 99.98 @ 10 microns

The APFC Series is designed to chemically adsorb corrosive or odorous gas vapors that are too small for conventional air filters to capture. Ideal of protecting centrifugal compressors and turbines in harsh, corrosive atmospheres, while reducing inlet noise.

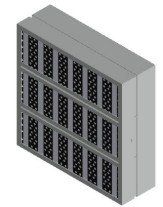

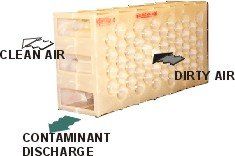

AFPI INERTIAL SPIN

AFPI Inertial Spin Series Three STAGE Air Intake Filter/Silencer

Flow Rates To 40,000 SCFM

Efficiencies to 99.98 @ 10 microns

Designed for heavy dirt load environments where contaminates like flyash, dirt, and sand can be a problem for standard air intake filters. The AFPI series greatly increases the service life of second and third stage elements by removing the bulk of the contaminant and discharging it through bleed air duct.

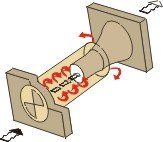

HOW IT WORKS

SECOND STAGE AND THIRD STAGE ELEMENTS

Second and third stage elements can be any combination of Industrial Filter Manufacturers high efficiency filters used in the AFP Single Stage Series, AFP Two Stage Series or AFPA Two Stage series, depending on desired efficiencies.