MIST ELIMINATORS

Industrial Filter Manufacturers offers small, medium and large capacity intake filters and filter / silencers for the protection of air compressors, blowers, engines, and turbines. Standard air intake filters have capacities up to 40,000 CFM with outlet sizes up to 42" diameter. All models are furnished with rugged weather hoods. Standard materials are carbon steel and are furnished with rust preventative primer coating beneath all weather paint.

The AF, AFE, and AFS SERIES incorporate a "radial fin" design which offers maximum filter area, low-pressure drop, and a large dirt holding capacity for long element life. Standard models are furnished with a felted polyester medium rated at 98% efficiency on particle sizes 10 microns and larger. After several cleanings, most elements can be returned to the factory for rebuilding. (See Rebuilding Services)

The AFP two and three stage panel filter series incorporate a panel style element with efficiencies up to 99.98% of 0.3 microns.

Custom design and materials are available on all models to meet higher flow rates and special applications.

MIST ELIMINATORS

AE Series Exhaust Filters

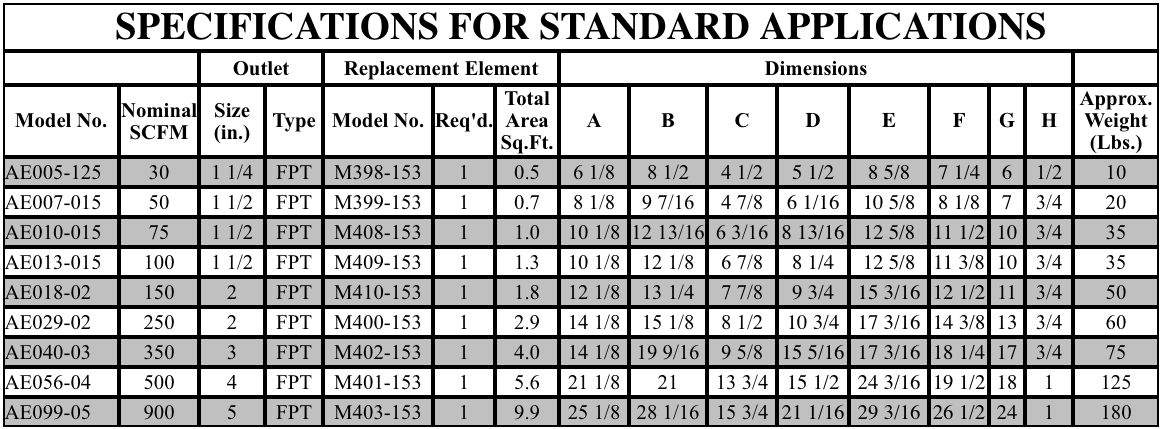

Model AE005-125 - AE037-06

Connection Size: 1/2" Thru 6"

Flow Rates To 1,200 SCFM

GRADED POROSITY COALESCING ELEMENT

DIRECT MOUNTING TO MACHINERY

LOW PRESSURE DROP

MINIMIZES OIL LOSS AND ALLOWS RECYCLING

ECONOMIC REPLACEMENT ELEMENTS

CUSTOM ELEMENTS AND HOUSING DESIGNS

SPECIFICATIONS

The AE series "oil mist and smoke eliminators" feature a highly efficient coalescing design element. The element uses a graded porosity medium to effectively remove the heavy concentrations of smoke from the exhaust stream of oil-sealed, oil lubricated, mechanical vacuum pumps. The filter can also be used in special applications as a mist eliminator when it is installed on the vent connection of compressor oil sumps, or liquid tank reservoirs. Coalescing is a "gathering" of minute liquid droplets to form larger droplets. The small droplets that enter the inside of the element are intercepted by the filter medium and extracted from the gas stream. The larger droplets drain off the outside of the element and fall by gravity to the bottom of the filter housing where a drain connection is provided for removing the coalesced oil. The element actually becomes more efficient as it is saturated with liquid, and will provide a long service life. At rated flow, the initial pressure loss is approximately 2.5 PSI. Filter oversizing or the use of special element materials is recommended for applications where lower differential pressure is required.

ELEMENT DESIGN AND CONSTRUCTION

The element is constructed with various high efficiency inner layers to coalesce the fine droplets, and coarser outer layers to promote drainage and prevent reentrainment. The element seals are composed of a molded, flexible, oil-resistant plastisol material which provides for a positive leak-tight seal. Standard elements are designed for flow rates up to 1500 SCFM and provide 0.3 micron retention at 99.97% efficiency. The elements may be modified to satisfy each original equipment manufacturer's requirements for specific chemical resistance, separation efficiencies, flow rates, and differential pressure levels.

ELEMENT DESIGN AND CONSTRUCTION

The element is constructed with various high efficiency inner layers to coalesce the fine droplets, and coarser outer layers to promote drainage and prevent re-entrainment. The element seals are composed of a molded, flexible, oil-resistant plastisol material which provides for a positive leak-tight seal. Standard elements are designed for flow rates up to 1500 SCFM and provide 0.3 micron retention at 99.97% efficiency. The elements may be modified to satisfy each original equipment manufacturer's requirements for specific chemical resistance, separation efficiencies, flow rates, and differential pressure levels.